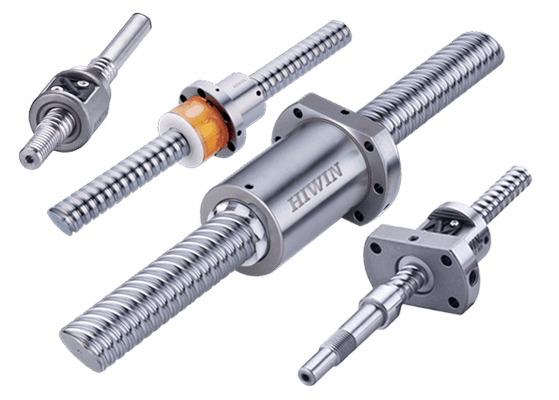

Ballscrews consist of a screw spindle and a nut integrated with rolling elements that cycle through a return mechanism. Ballscrews convert rotary motion into linear motion, and are most commonly used in industrial machinery and precision machines. Hiwin Corporation provides a wide range of ballscrew configurations to satisfy your special application requirements. Hiwin has the capability of producing JIS C0 class ground ballscrews, and DIN 5 class (up to 23 microns) for precision rolled ballscrews. Ballscrew O.D. ranging from 4mm to 120mm, and with Dm-N values up to 220,000.

Series

Precision Ground Ballscrew

Hiwin precision ballscrews are made through a grinding process of the screw spindle. Precision ground ballscrews provide high positioning accuracy and repeatability, smooth movement and long service life. These highly efficient ballscrews are a perfect solution for a variety of applications.

Rolled Ballscrew

The major differences between a rolled and ground ballscrew are the manufacturing process, the lead error definition and geometrical tolerances. Hiwin rolled ballscrews are made through a rolling process of the screw spindle instead of a grinding process. Rolled ballscrews provide smooth movement and low friction which can be supplied quickly from stock, at a lower production cost.

Super S Series

The Super S series uses a patented design return system that can absorb ball impact noise which greatly reduces the noise intensity and allows the ballscrew to sustain peak performance in rigorous environments. The modified return system improves the strength of the return structure which increases the Dm-N value and reduces the ball nut diameter by 18%-32%.

Super T Series

The Super T series circulation path has the elements leaving the ball track tangential to the PCD and coordinating with the lead angle of the ballscrew shafting. This optimal design not only reduces the noise level but also vibrations leading to smoother rotation.

Super Z Ballscrew

Tangential circulation path improves speed and reduces noise and vibration. The nut’s diameter is 15% – 30% smaller, making it perfect for smaller spaces.

Miniature Ground Ballscrews

Hiwin miniature ground ballscrews are made through a grinding process of the screw spindle. Miniature ground ballscrews are compact, perfect for those smaller load and shorter stroke applications. These highly efficient ballscrews provide high positioning accuracy and repeatability, smooth movement and long service life.

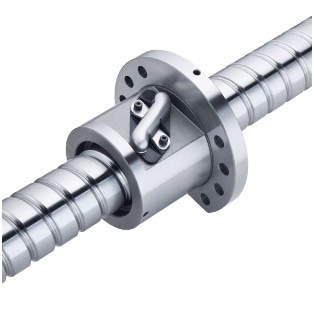

R1 Series Rotating Nut

Hiwin’s rotating nut utilizes a special end cap design that allows the steel balls to circulate inside the nut while featuring an integral bearing that allows the ballscrew shaft to be fixed. This unique design reduces noise generated at high speeds and offers higher axial loading and stiffness.

Heavy Load Series

Heavy load ballscrews offer 2-3 times higher loading capacity than a standard ballscrew series. They have reinforced circulation systems that are suitable for high speed conditions and are able to achieve a longer service life.

Accessories

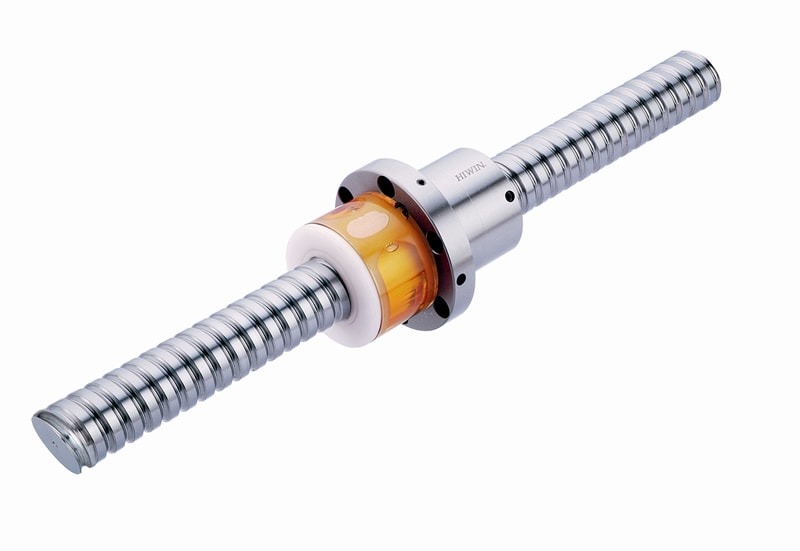

E2 Series Self-Lubricant

The E2 self-lubricating kit makes sure a ballscrew is properly lubricated for long periods of time, saving cost by extending the time interval between scheduled maintenance. Our kit is easy to install and maintain providing a clean and environmentally friendly way to sustain a machines longevity.

Dust Proof Options

Dust-proof options are designed to prevent particles or debris from entering the ball nut, especially for application environments involving saw dust, iron filings, etc. Hiwin offers multiple options for dust-proofing a ballscrew which are perfect solutions for contamination prevention.

Cool Type I Series

The cool type series ballscrews utilize forced cooling to minimize heat generation and thermal expansion during ballscrew operation. The forced fluids keep the shaft and ball nut temperature uniform, increasing the strength durability and extending the expected service life of the ballscrew.

Cool Type II Series

The cool type series ballscrews utilize forced cooling to minimize heat generation and thermal expansion during ballscrew operation. The forced fluids keep the shaft and ball nut temperature uniform, increasing the strength durability and extending the expected service life of the ballscrew.

Retrofit Kits

Hiwin offers ballscrew retrofit kits for manual milling machines. These ballscrew kits are available in stock sizes and grades that meet various CNC system requirements. The complete kit would provide both the x and y axis ballscrew assemblies with yoke.