Highly accurate, non-contact motors, HIWIN linear motors offer a variety of sizes and model types, enabling designers to choose the best fit for the application’s peak force and continuous force in the allowable space. HIWIN direct drive permanent magnet synchronous linear motor components can be iron-core or ironless-core.

Components

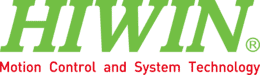

LMSA Series

HIWIN synchronous linear motors LMSA are the power packs of linear drives. They are especially distinguished by very high power density and minimum cogging force. The three-phase motors are composed of a primary part (forcer) with a coiled stack of sheets and a secondary part with permanent magnets (stators). With the combination of several stators, many stroke combinations are possible.

Features:

- 3-phase AC

- High thrust

- Excellent acceleration

- Low cogging

- Many stroke lengths

- Several forcers possible on one stator

- Peak force 2850 N

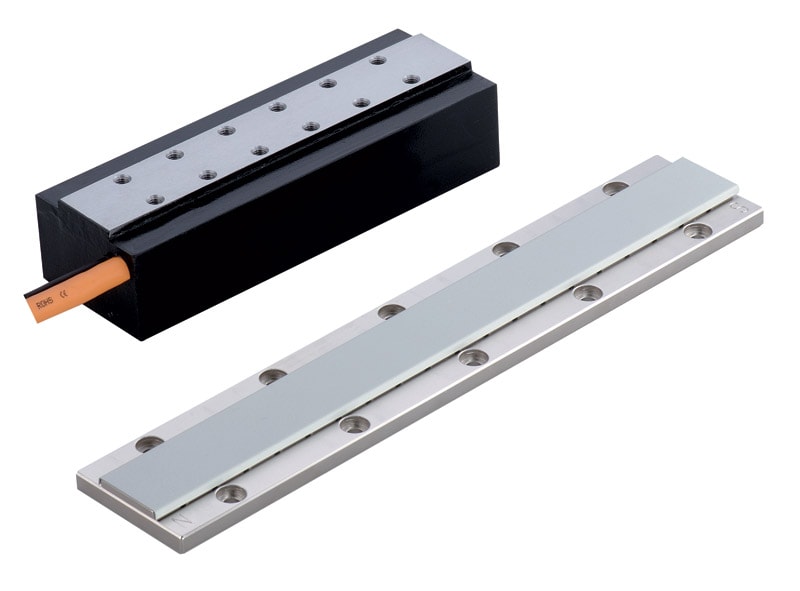

LMC Series

HIWIN synchronous linear motors LMC are the born sprinters. They are light, extremely dynamic. This is due to their coreless primary part (forcer) with epoxy cast coils, it needs to move very little of its own weight. The secondary part is composed of a U-shaped stator made of permanent magnets.

Features:

- 3-phase

- Extremely dynamic

- Good synchronization and high speed consistency

- Low inertia and high acceleration

- Low profile

- No cogging

- Several forcers possible on one stator

- Peak force 780 N

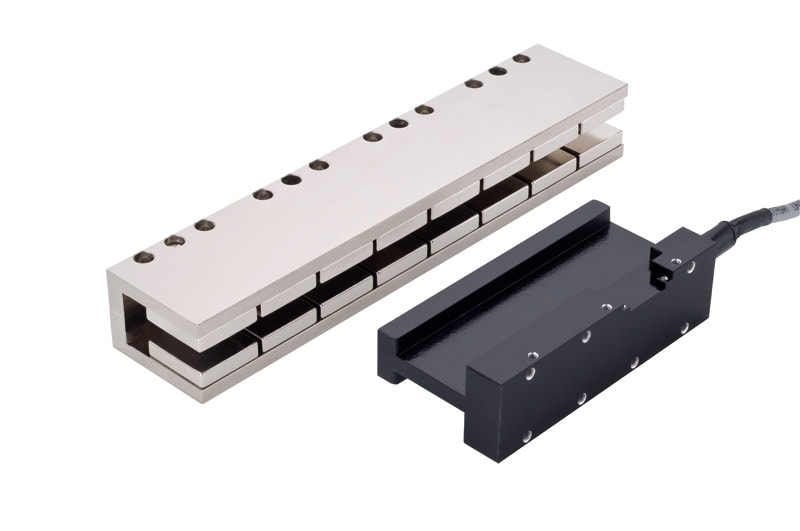

LMFA Series

HIWIN synchronous linear motors LMFA are coiled stack of sheets with water-cooling loop. They are especially distinguished by very high power density and minimum cogging force. This three-phase motor is composed of a primary part (forcer) with iron core and secondary part (stator) with permanent magnets. With the combination of several stators, many stroke combinations are possible.

Features:

- 3 phase

- Water-cooling

- UL certification

- Low cogging

- Unlimited stroke

- Peak force 7328 N

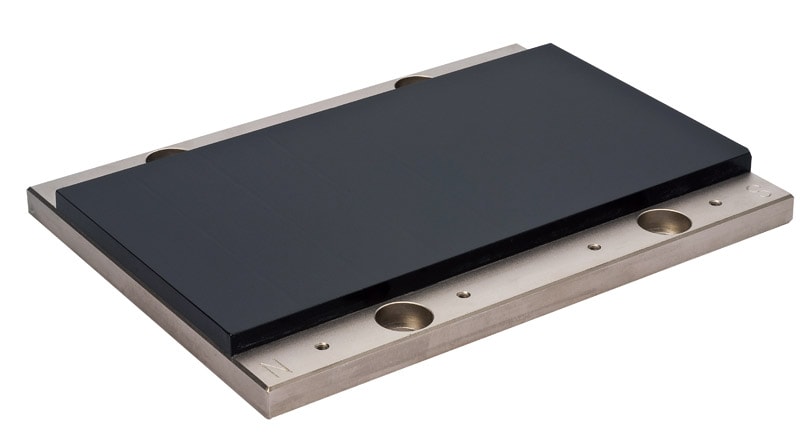

LMT Series

HIWIN Linear tubular LMT series are linear motors with the unique shape by arranging cylindrically permanent magnets. Due to the coreless forcer, the LMT tubular motors are very light and extremely dynamic. They are also good substitutes for ballscrew applications, because of the same installation interface.

Features:

- 3-phase

- Low mass and high acceleration

- Extremely dynamic

- Wide air gap and easy assembly

- No cogging and no contact

- No wearing

- Multiple forcers

- Peak force 980 N