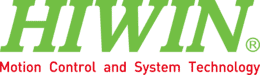

HIWIN Corporation Torque Motor Rotary Tables (TMRT) use a direct-drive torque motor, built-in high-rigidity and high-precision bearings, absolute encoders and powerful brake system to ensure excellent acceleration capabilities and high precision uniform movements. HIWIN TMRTs are backlash-free, optimized for high torques, have robust dynamics and are highly adaptive to the most demanding of automation processes. Compared with the mechanical indexing table, TMRT has high speed and high torque characteristics, suitable for the needs of various machining equipment.

Series

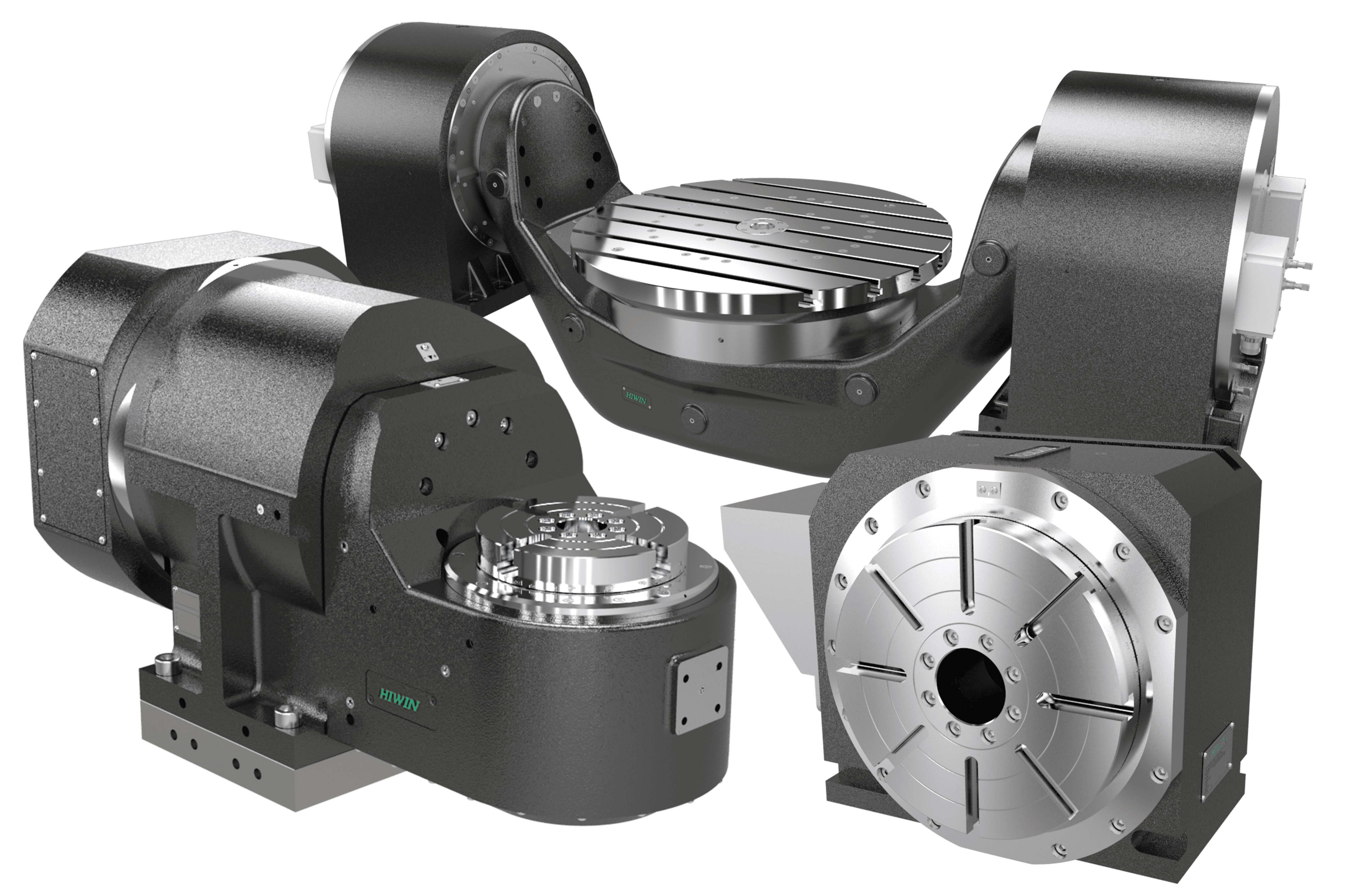

RAB Series

Key features of the RAB Series torque motor rotary tables

- Symmetrical trunnion motion design.

- High positioning accuracy, suitable for high-precision simultaneous machining.

- Built-in powerful air brake system.

- Widely used in 3+2 axis, 4+1 axis positioning processing or 5-axis simultaneous processing.

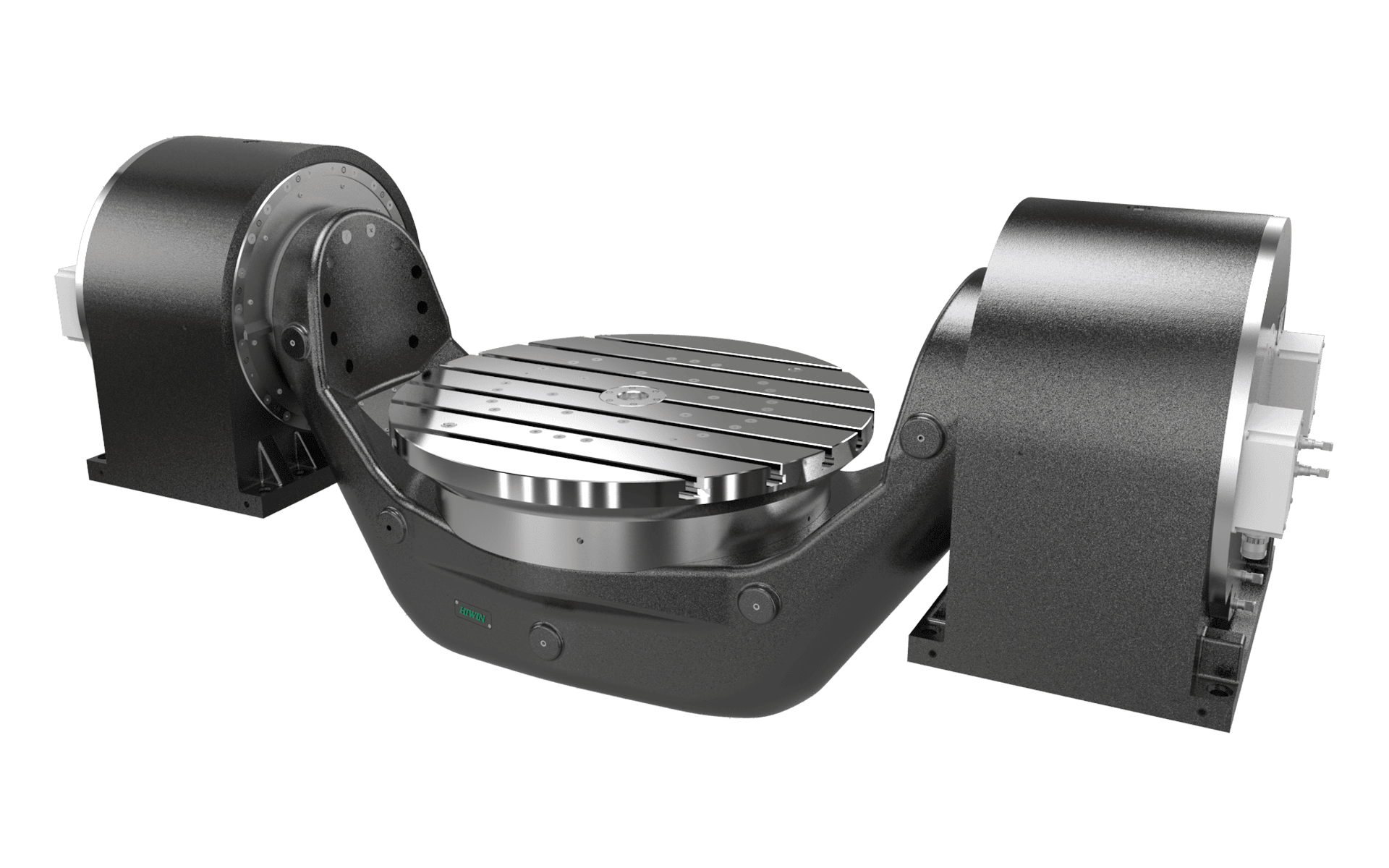

RAS Series

Key features of the RAS Series torque motor rotary tables

- Single arm rotary table, compact structure, suitable for five-axis machine design with limited space.

- High-response simultaneous processing performance.

- Widely used in 3+2 axis, 4+1 axis positioning processing or 5-axis simultaneous processing.

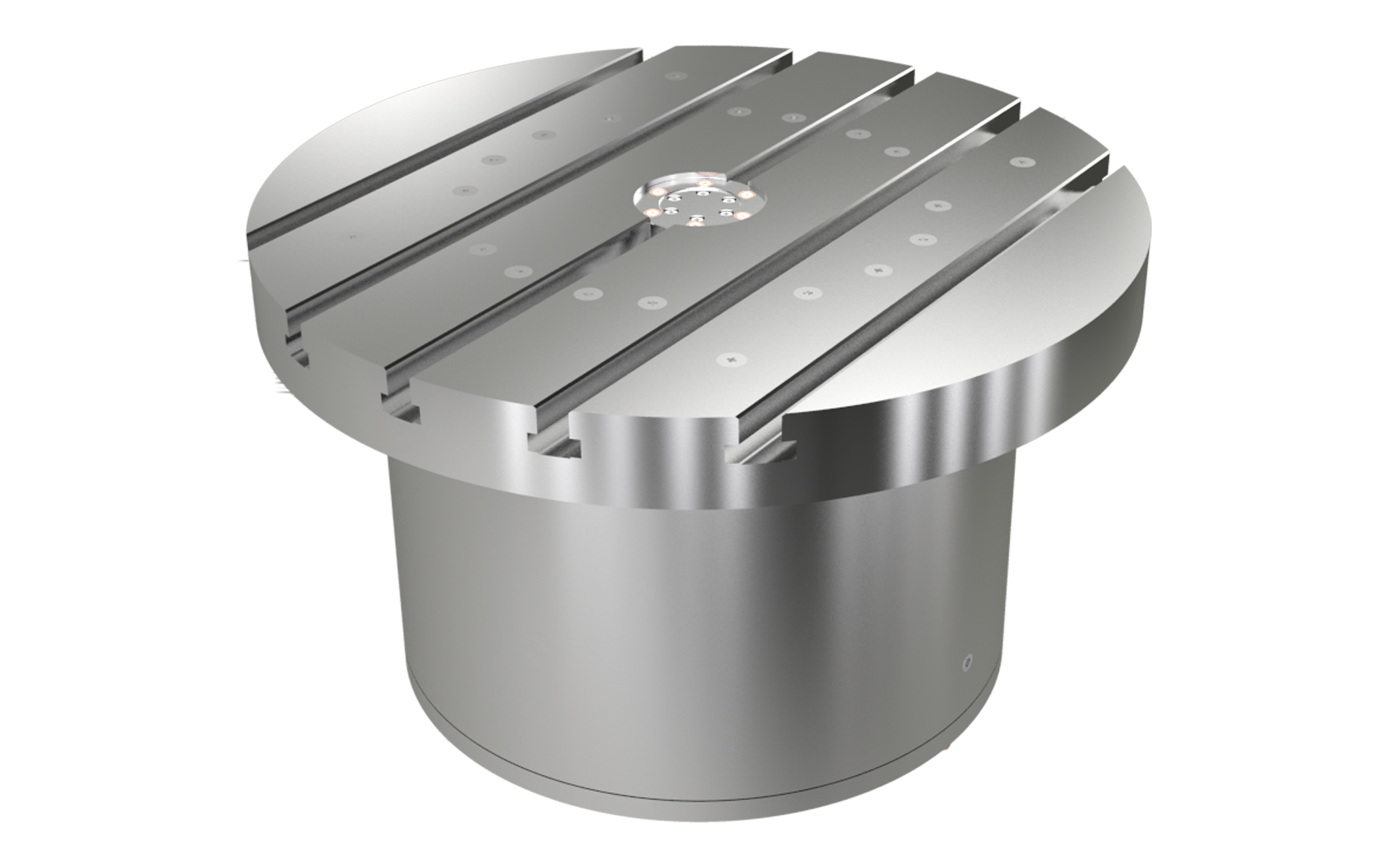

RCV Series

Key features of the RCV Series torque motor rotary tables

- Best vertical choice for upgrading a processing machine to 3+1 axis.

- Used high rigidity bearing.

- High positioning and high repeatability can be achieved by using high-precision encoder.

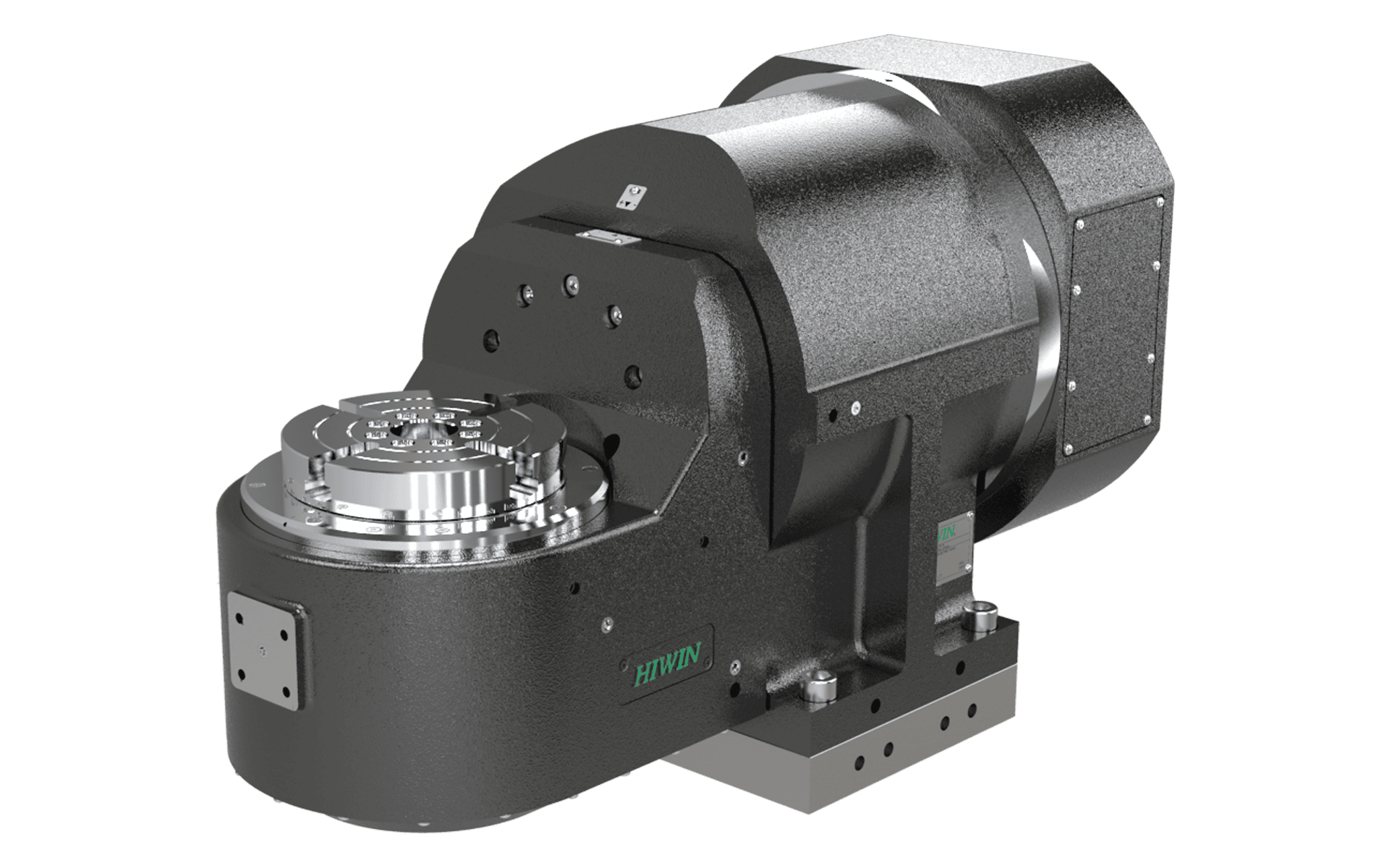

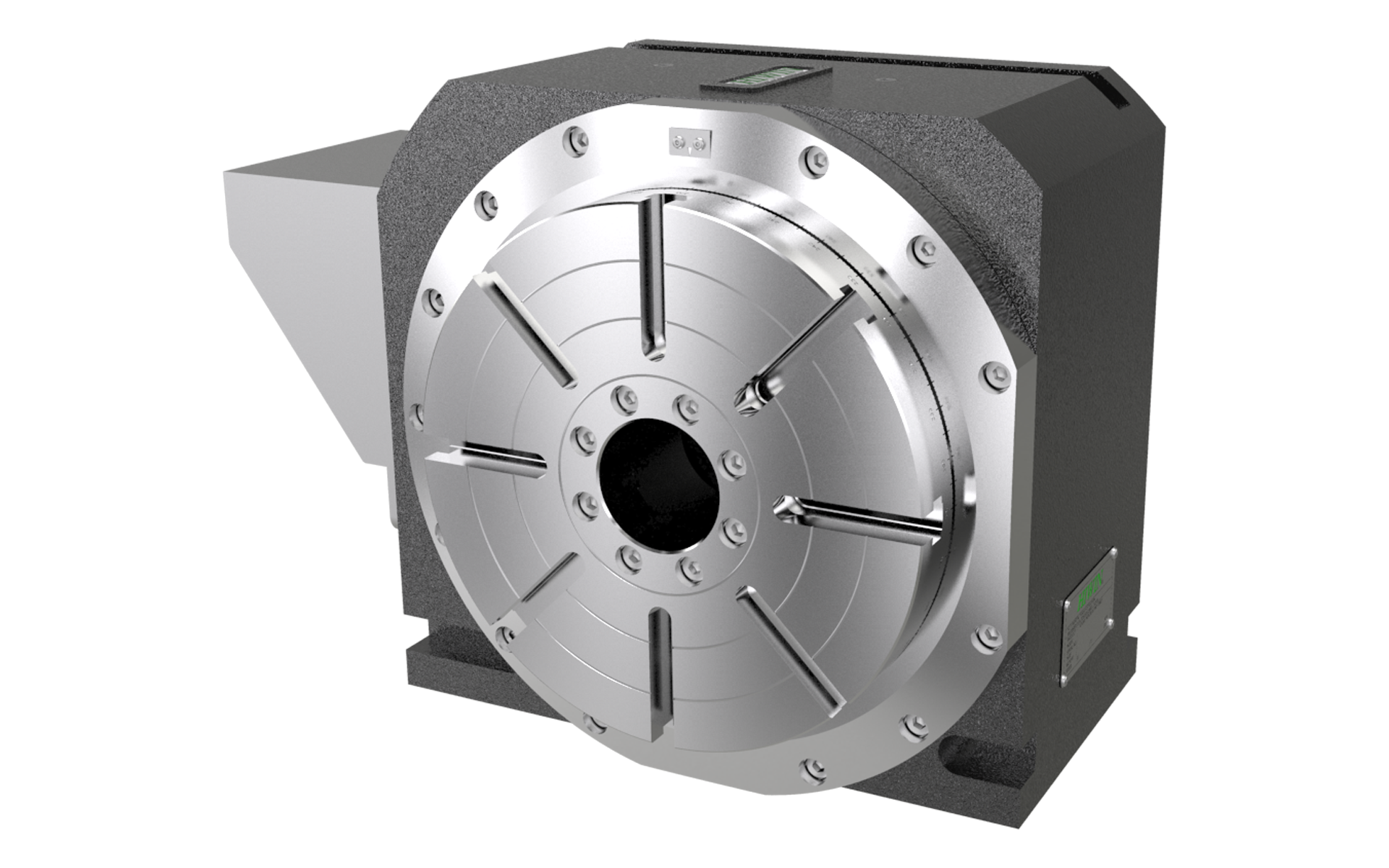

RCH Series

Key features of the RCH Series torque motor rotary tables

- Best horizontal choice for upgrading a processing machine to 3+1 axis.

- High dynamic performance positioning rotary table.

- High accuracy of allowable deflection.

- Integrated milling, turning and grinding application.

Torque Motors

IM-2 Series

Key features of the IM-2 torque motor

- Water Cooling

- Cogging torque is reduced down to 50%

- Milling and Turning Composite Machine Application