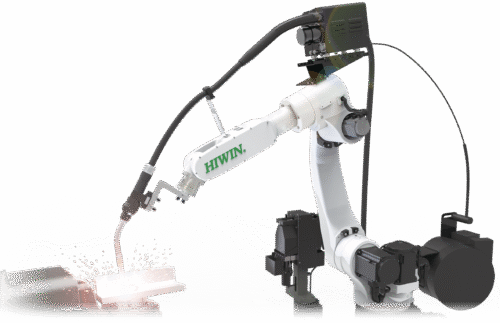

HIWIN Welding Robot: Precision Meets Flexibility

Welding automation should enhance your workflow, not force you to rebuild it. That’s why HIWIN’s welding robot is engineered to integrate seamlessly with the welding systems and suppliers you already trust — whether that’s Lincoln Electric, Miller, SKS, or others. Instead of starting from scratch, you get a system that combines precision, reliability, and scalability with the freedom to choose what works best for your shop.

Freedom to Choose

Every manufacturer has preferred processes, equipment, and partnerships. HIWIN’s open-architecture design ensures you’re not locked into proprietary software or a single supplier. From control systems to welding torches, our robot adapts to your environment, making integration smooth, cost-effective, and aligned with how your team already works.

Built for Accuracy and Reliability

With a repeatability of ±0.05 mm, HIWIN’s welding robot sets a high bar for precision. But accuracy is only part of the story. Features like TCP auto-recovery keep production on track by correcting torch misalignment in real time, while the Smart-Weld interface lets operators adjust parameters directly through the control system. Add real-time monitoring and error alerts, and you get consistent weld quality with minimal downtime.

Seamless Integration

HIWIN’s robot is designed to work with industry-leading platforms such as Lincoln Electric’s Waveform Control Technology, Miller’s Auto-Set™, and SKS’s spatter-reduction programming. Out of the box, it comes with:

- Inclusive software with no hidden licensing fees.

- A single teach pendant to control the robot, external axes, and power supply.

- Optional sensing technology like laser seam tracking and touch sensing.

- Expansion options including seventh-axis units and servo tables.

The result is faster setup, reduced retraining, and a system that grows with your production demands.

Future-Proof Flexibility

Manufacturing never stands still. HIWIN’s open-compatibility design means you can upgrade power sources, swap torches, or add new software without replacing your entire system. That flexibility protects your investment and ensures your automation keeps pace with future requirements.

Why It Matters

HIWIN’s welding robot delivers practical benefits that impact both productivity and profitability:

- Shorter lead times with faster integration.

- Lower costs by leveraging the equipment you already own.

- Operator familiarity with trusted systems.

- Scalability to support evolving processes and customer demands.

- High precision and uptime where consistency matters most.

Conclusion

With HIWIN’s welding robot, automation doesn’t come with limits. It brings the precision to meet exacting standards, the flexibility to adapt to your environment, and the scalability to prepare for what’s ahead. That’s how we help manufacturers focus on what matters most: precision, productivity, and profitability — today and tomorrow.

See It Live at FABTECH 2025

You don’t have to take our word for it — come experience the HIWIN welding robot in action. Visit us at FABTECH 2025 in Chicago, Booth #B13027, or stop by the MITUSA booth, #B11000, to see firsthand how HIWIN delivers precision and flexibility in welding automation.